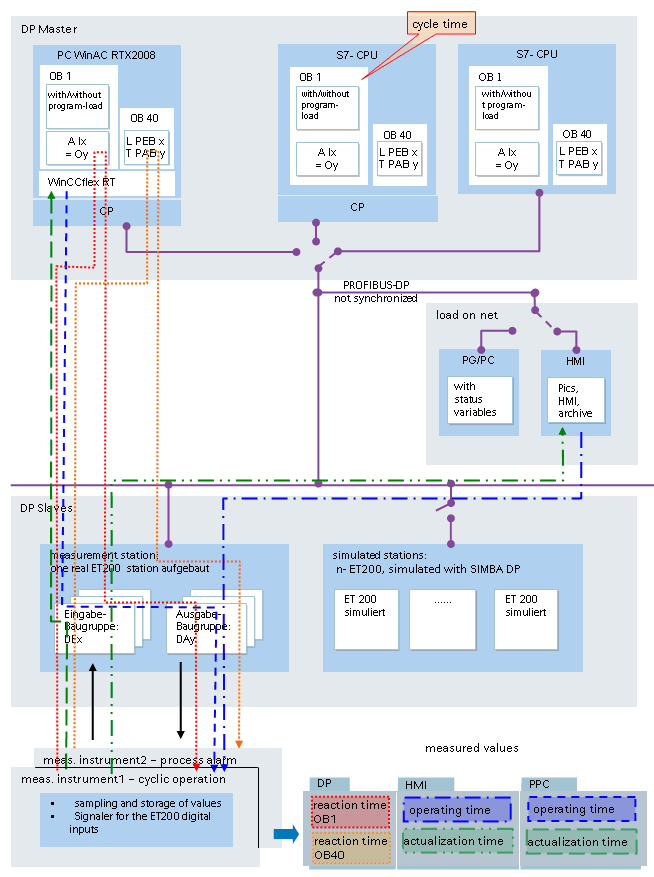

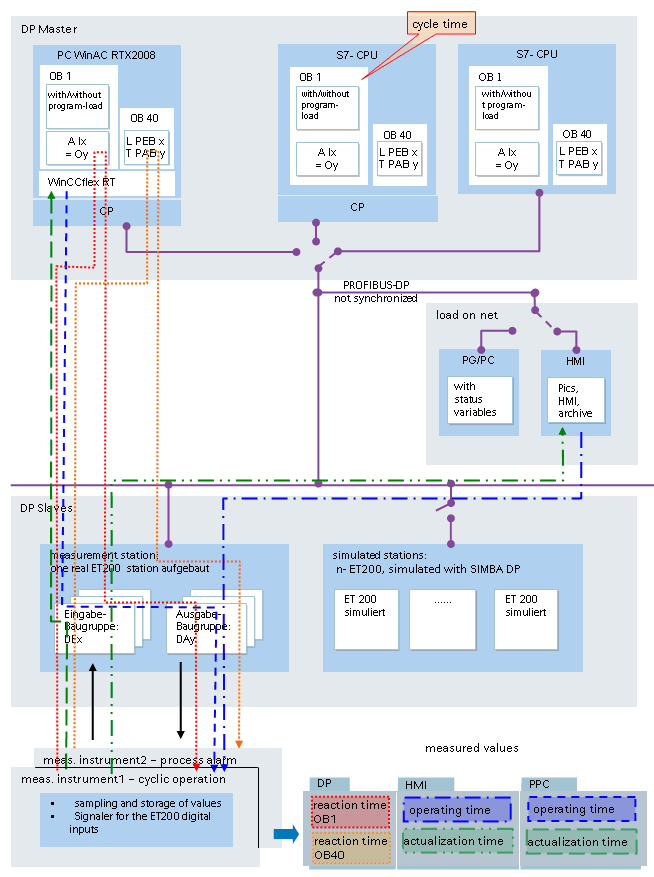

ET200 stations with different configurations are connected to different SIMATIC DP masters via PROFIBUS DP.

One ET200 station is really set up. The transit time of the I/O signal is measured via this station.

All other ET200 stations are simulated.

A measuring instrument that is connected to a specific ET200 measurement station records the reaction times as follows:

For 90 % of the configured I/O bytes, the DP master reads and writes the distributed measurements via the process image. For 10 % of the configured I/O bytes, these measurements are read and written via process alarms and direct commands.

To ensure that the practical relevance of the measurements is as high as possible, the measurements are additionally performed with practical loads.

These loads are:

Load program in the DP master, consisting of OB1 cycle and possible HMI Runtime configuration.

Up to 10 operator panels (TP) on the same DP line as the ET200 stations.

Typical images, in which variables from the DP master are displayed, are configured in the operator panels.

1 programming unit (PU) on the same DP line as the ET200 stations.

The programming unit accesses the DP master online using the "Status" function.